How Structural Steel Channels Are Made

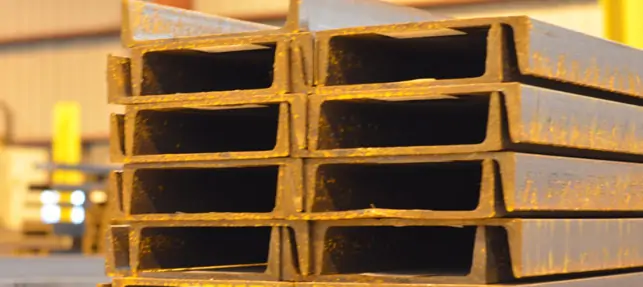

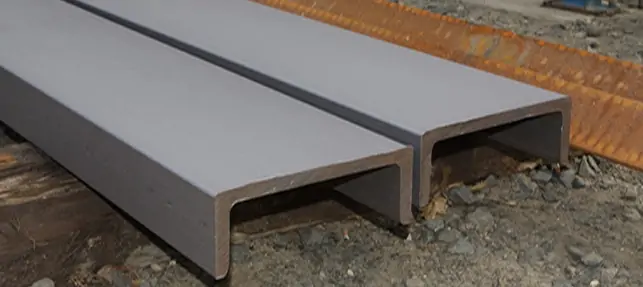

Structural steel channels are a staple in construction and manufacturing thanks to their durability, versatility, and strength. These channels are produced through a hot-rolling process where mild carbon steel strips are heated to high temperatures, making them malleable. They are then passed through rollers to form the characteristic “C” shape, which features a broad vertical web and two flanges. Depending on the design specifications, these flanges can be parallel or tapered. The steel is then cooled and shaped into its final form.

In addition to improving consistency in structural channel dimensions, the hot-rolling process enhances the material’s strength and ability to withstand heavy loads. As a result, structural channels are a dependable solution across a variety of applications, from building braces and frames to supports for heavy equipment.

Applications of Structural Steel Channels

Structural steel channels are widely used in residential and commercial construction, industrial applications, and transportation. Their inherent strength and ease of use make them ideal for many structural and framing purposes, such as:

- Wall Framing: Channels can be installed vertically to support the weight of a structure’s walls, functioning similarly to studs in warehouses, garages, and storage facilities.

- Siding Attachment: Installed horizontally between poles, steel channels act as mounting arms for both interior and exterior sheet metal siding.

- Roof Rafters: In both light-duty and heavy-duty roofs, channels can either run from eave to ridge or span perpendicularly across I-beam rafters to support the roof deck and extend spacing between beams.

- Window and Door Frames: Installed in four parts, channels with mitre joints on every end create a flat surface where the window or door can be securely mounted.

- Wood Beam Reinforcement: When additional support is needed in a wood-framed building, steel channels can be placed under or around the hardwood beams to improve load-bearing capacity.

- Vehicle Frames: Structural steel channels are often used in car and trailer frames. Heavy-duty channels serve as the primary support rails, while lighter channels form cross braces and substructures.

- Industrial Buildings: Channels are integral in industrial and commercial building construction for their strength and load distribution capabilities.

- Infrastructure: Bridges, stair stringers, guardrails, and joists are often made of high-strength structural steel channels.

Benefits of Structural Steel Channels

Structural steel channels have several advantages that make them a smart choice for engineers, builders, and designers alike. Here are some of the specific benefits of using structural steel channels:

- Enhanced Strength: Structural steel channels are designed to handle significant stress and weight. This equips them to reinforce load-bearing structures without unnecessary bulk.

- Cost-Effective Construction: These components provide exceptional performance while remaining budget-friendly by lowering material and labor costs over the life of a project.

- Improved Safety: Their reliable performance under harsh conditions ensures safer buildings and infrastructure capable of withstanding extreme environmental factors such as wind, snow, and seismic activity.

- Design Flexibility: Because channels can be fabricated in various sizes and shapes, architects and engineers can find customized solutions that meet structural and aesthetic needs.

- Streamlined Assembly: Thanks to their ease of fabrication and compatibility with other building components, channels simplify installation and reduce overall assembly times.

- Long-Term Durability: Constructed from high-quality steel, structural channels are resistant to corrosion, wear, and weathering. This makes them ideal for projects that require long-lasting performance with minimal maintenance.

Source Your Steel Channels from Infra-Metals

As one of the largest structural steel service centers in the United States, Infra-Metals delivers high-quality steel channel products to meet the demands of your next project. Our centers are tailored to meet the specific needs of the regions we serve, making us a go-to partner for companies nationwide. We have a vast inventory of steel channel sizes, lengths, and specifications, including ASTM A36, A709, A992, A588, and A572.

Beyond channels, our comprehensive inventory of structural steel products includes wide flange beams, tube, plate steel, angles, bars, I-beams, pipe, sheets, and solar panel mounts. We also offer steel plate burning, saw cutting, drilling, forming, and other extensive processing capabilities.

Whether you’re reinforcing a warehouse wall, framing a trailer, or supporting a heavy roof structure, Infra-Metals provides the structural channel products and expertise you need. We will work with you to find the best solution for your project, no matter your location. Request a quote today to get started.

Specifications

ASTM A36

Standard specification for carbon structural steel. This specification covers shapes of structural quality for use in riveted, bolted, or welded construction of bridges and buildings, and for general structural purposes. Learn More+

ASTM A709

Standard specification for carbon and high-strength low-alloy shapes. This specification covers shapes, and bars intended for use in bridges. Seven grades are available in four yield strengths. Learn More+

ASTM A992

Standard specification for steel for structural shapes for use in building framing. This specification covers rolled shapes for use in building framing or bridges, or for general structural purposes. Learn More+

ASTM A588

Standard specification for high-strength low-alloy structural steel. This specification covers shapes for welded, riveted, or bolted construction but intended primarily for use in welded bridges and buildings where savings in weight or added durability is important. The atmospheric corrosion resistance of this steel in most environments is substantially better than that of carbon steels with or without copper addition.Learn More+

ASTM A572

Standard specification for high-strength low-alloy structural steel. This specification covers five grades of high-strength low-alloy shapes intended for riveted, bolted, or welded construction of bridges, or for other construction applications. Learn More+