Steel angles are utilized in various industries for a broad range of purposes. They are commonly employed in framing, but they are also used for brackets, trim, reinforcements, and various other applications.

Infra-Metals offers structural angles in different sizes, lengths, and specifications that you can use for your next project. We are one of the major structural steel service suppliers in the United States, offering an extraordinarily diverse range of products and services. Moreover, we specially design our facilities to match the demands of the regions we serve, and we remain committed to providing high-quality items and services in a timely and cost-effective manner.

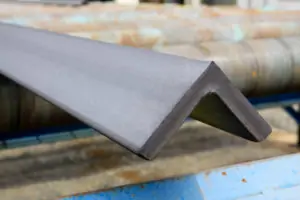

What Are Steel Angles?

Steel angles are one of the most prevalent building materials used in construction. They make the frame of structures like walls, roofs, and floors and can create trusses, braces, and support beams. Additionally, they are essential for various construction projects, as they add strength and stability to any structure.

Steel angles come in various sizes and shapes, which can be cut to your desired length and bent to any angle. They are also available in multiple grades and finishes, including galvanized and stainless steel.

Advantages of Using Steel Angles

The following are some of the main advantages of utilizing stainless steel angles in your next construction project:

Versatility

Due to their extreme flexibility, using steel angles for your project provides countless design options. For example, they may be cut to size or combined with other materials to create durable window frames, bracing, shelves, railings, decks, or cladding.

Clip Angle connections are used for connecting a floor beam to another beam, or a column to a beam. The attached beam can be sloped to the main one. The angles are bolted or welded to the main beam.

Durability

Buildings, regardless of size, need to be sturdy and safe for everyone. To accomplish this, builders utilize only the best materials for the task. One example is steel angles, which are regarded for the extraordinary strength and stability they provide to structures.

Easy To Maintain

Because they don’t require expensive materials to maintain quality over time, structures made of steel angles are often low-maintenance. In addition, these structural materials may be available in mill-finished or coated forms that increase corrosion resistance and shield the metal from rust in the long term.

Lightweight

Steel angles are one of the lightest building materials because of their compact design, making them ideal for even modest projects. Aside from building, they are frequently used in furniture, shelving, cabinets, tables, and other modular designs.

Sustainability

Due to their ability to be recycled, steel angles are a good option for sustainability. They may be refined and re-processed into new steel products without affecting their original qualities.

Cost-Efficient

Steel angles are incredibly simple to fabricate in terms of applied strength, making them a cost-effective option for projects with a limited budget and buildability.

Applications of Steel Angles

Steel angles can be applied to various projects. Here are the common applications of steel angles:

Constructions

Steel angles are used in several building construction tasks, whether for supporting columns or beams. In addition, they can be used for railings, rafters, wall studs, ceiling support, and concrete reinforcement, depending on the design. Their benefit to the industry continues to be unrivaled, allowing construction firms or contractors to develop new and novel methods to use this material.

Bridges

The three main components of a bridge include the foundation, substructure, and superstructure. Each supports the whole structure and allows for even weight distribution so that automobiles and other vehicles may pass on the bridge deck.

Each of these portions has a steel angle supported by various metal items. For instance, sheet piles in the foundation can be supported by angle bars to give greater grounding and load capacity. They can also be used in substructures to provide extra wall retention capabilities for vertical supports.

Manufacturing

The metal manufacturing business is one of many that rely on steel angles for structures, equipment, and overall operations. The basic steel angle has several applications in food and beverage, apparel, wood processing, chemical refineries, oil and gas industries, and more.

Quality Steel Angle From Infra-Metals

To this day, Infra-Metals is one of the most trusted service centers for structural steel products and services in the United States. We are part of the Reliance, Inc. family, a unified network that executes efficient operations and quality metalwork with quick turnaround times.

Our decades of expertise and experience provide high-quality services at reasonable pricing! Furthermore, our skills enable us to provide the services you require when you require them.

Choose Infra-Metals for all your steel angle product and service needs! Contact us today and request a quote.

Specifications

ASTM A36

Standard specification for carbon structural steel. This specification covers shapes of structural quality for use in riveted, bolted, or welded construction of bridges and buildings, and for general structural purposes. Learn More+

ASTM A709

Standard specification for carbon and high-strength low-alloy shapes. This specification covers shapes, and bars intended for use in bridges. Seven grades are available in four yield strengths. Learn More+

ASTM A992

Standard specification for steel for structural shapes for use in building framing. This specification covers rolled shapes for use in building framing or bridges, or for general structural purposes. Learn More+

ASTM A588

Standard specification for high-strength low-alloy structural steel. This specification covers shapes for welded, riveted, or bolted construction but intended primarily for use in welded bridges and buildings where savings in weight or added durability is important. The atmospheric corrosion resistance of this steel in most environments is substantially better than that of carbon steels with or without copper addition. Learn More+

ASTM A572

Standard specification for high-strength low-alloy structural steel. This specification covers five grades of high-strength low-alloy shapes intended for riveted, bolted, or welded construction of bridges, or for other construction applications. Learn More+