Sustainability of Structural Steel

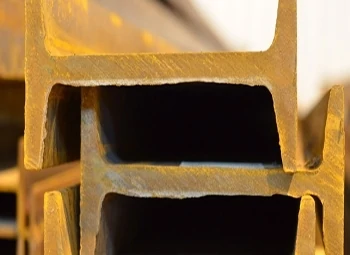

Leave a CommentDue to its strength and durability, structural steel is one of the most important materials used in construction. It is vital in building applications ranging from framing to roofing to support structures and more. Because of its widespread availability and reusability, structural steel will continue to be a key resource in current and future building projects. Without structural steel, many construction projects would not be possible. However, manufacturing new steel can have major environmental effects, as these processes often require a substantial amount of energy.

Recycling structural steel is an effective method for reducing the building industry’s environmental impact. Steel is a highly recyclable material that can be reused without deteriorating quality or durability. Moreover, recycling requires less energy than creating new products, reducing carbon dioxide emissions.

This article will explore structural steel recycling and how this can contribute to a more sustainable future.

How Is Steel Recycled?

As consumers become more aware of the environmental impact of the construction industry, they are looking for more sustainable options for their building projects. Recycling structural steel can be a key component of these practices.

First, scrap yards collect and purchase various types of discarded steel from homeowners, companies, and other metal users. The scrap yard then sorts the steel by type, quality, color, and weight before processing and shredding them into smaller pieces. Rail cars transport the sorted, shredded steel to regional steel mills for recycling.

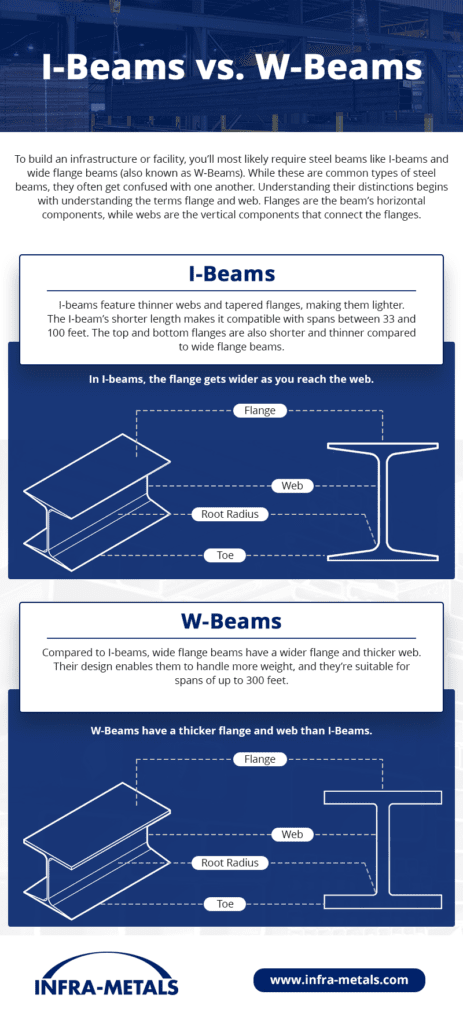

Structural steel recycling consists of gathering steel scrap from diverse origins and meticulously classifying it according to its type and quality. The sorted scrap is subsequently subjected to melting in furnaces, utilizing either Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF) methods. The steel attains the desired composition through refinement, subsequently taking the form of beams, columns, or plates.

In the BOF method, molten iron is combined with scrap steel, and oxygen is blown into the furnace. This results in a chemical reaction that removes impurities and adjusts the carbon content to create high-quality steel. On the other hand, the EAF method uses electricity to generate intense heat, melting scrap steel in an electric arc furnace.

Remarkably, the recycled content of structural steel produced in the United States averages 93%, and steel is 100% recyclable. In contrast, other construction materials like reinforced concrete can only be downcycled. At the end of a building’s lifespan, 98% of all structural steel is recycled into new products—such as new buildings, automobiles, and home appliances—without losing physical properties. This makes structural steel a cradle-to-cradle material that can be recycled repeatedly, contributing to sustainable construction practices and resource conservation.

The Importance of Environmental Product Declarations

Environmental Product Declarations (EPD) are valuable tools in emphasizing the significance of recycling structural steel and meeting the requirements for sustainable, environmentally friendly construction materials. EPDs serve as comprehensive documents that provide transparent and credible information about the environmental impact of products.

Various rating systems exist to assess and certify the environmental performance of construction materials. These systems, such as LEED (Leadership in Energy and Environmental Design) and other regional rating systems, establish criteria for evaluating the sustainability aspects of building materials. The American Institute of Steel Construction (AISC) actively collaborates with steel mills to develop industry-wide EPDs that comply with these rating systems.

The manufacturing process of structural steel involves certain environmental impacts, which are evaluated and disclosed in EPDs. These impacts include global warming potential, ozone depletion, acidification, eutrophication, and ozone creation. EPDs also provide an overview of the life cycle of structural steel, from raw material extraction to manufacturing and transportation. This allows stakeholders to assess its overall environmental performance.

Benefits of Structural Steel Sustainability

Structural steel sustainability offers numerous benefits for a more environmentally friendly and economically viable construction industry. Being a highly recyclable material, steel is easily recoverable and recyclable at the end of a building’s life cycle. This recycling capability reduces the carbon footprint associated with steel production.

Steel’s strength and durability contribute to the longevity of structures. Steel buildings can have a longer lifespan compared to other construction materials, reducing the need for frequent replacements and renovations. This extended lifespan results in fewer materials consumed over time and lower environmental impacts.

Steel’s durability and low maintenance requirements lead to long-term cost savings for building owners. Furthermore, steel structures’ design flexibility and efficiency can result in reduced construction time and labor costs.

Choose Infra-Metals for Premium Structural Steel Supply and Services

Since 1990, Infra-Metals has been a leader in servicing the structural steel market! Our strategy is to focus on providing quality steel products and precision processing, enabling us to offer an array of services. These include plate burning, drilling, saw cutting, and forming. We also prioritize professional and ethical business practices with our customers, suppliers, and employees.

Contact us today to learn more about our services! You can also request a quote now.