I-Beam vs. Wide Flange Beam | A Steel Beam Guide

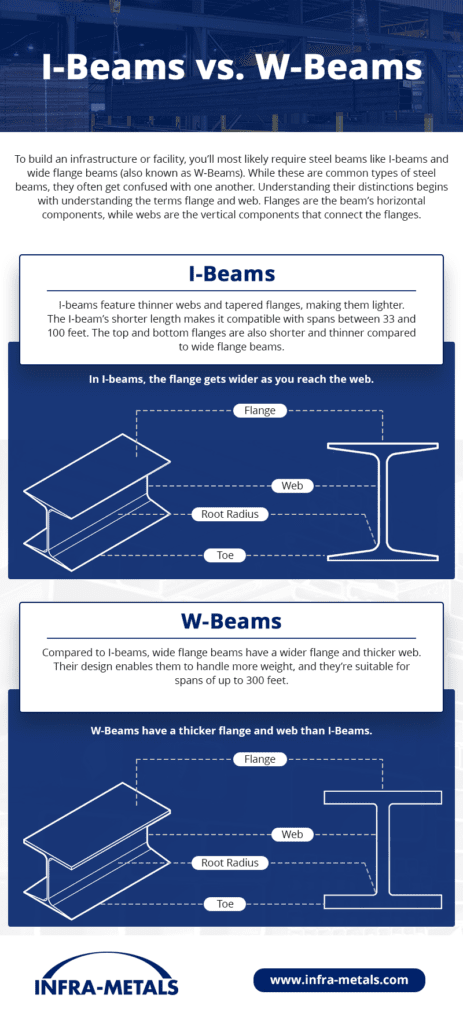

To build an infrastructure or facility, you’ll most likely require steel beams, like I-beams and wide flange beams. While these are common types of steel beams, they often get confused with one another. Understanding their distinctions begins with understanding the terms flange and web. Flanges are the beam’s horizontal components, while webs are the vertical components that connect the flanges.

Here we’ll review the differences and similarities between I-beams vs. W-beams, as well as how to select the right beam for your application.

What Is a Wide Flange Beam?

Sometimes called a W-beam, a wide flange beam is a type of steel beam shaped like a sideways H. The web can be of equal width or wider than the flange. The size of a W-beam is identified by the first number in the product description followed by the weight per foot. For example, a W21x44 beam measures about 21 inches in width and 44 pounds per foot. The web bears shear forces while the flange resists bending forces.

Many construction projects rely on wide flange beams, including:

- Bridges

- Factory platforms

- Support beams for steel buildings and factories

- Machinery

- Truck bed frames

What Is an I-Beam?

I-beams tend to have flanges that are shorter than the web, resulting in a cross-section shaped like a capital “I.” This design enables the beam to bend when high pressure is applied. W-beams offer more variety in sizes and lengths, whereas I-beams have a more limited selection.

I-beams appear in many structures, such as:

- Warehouses and factories

- Truck bed frames

- Support beams for facilities, construction, and engineering

- Support steel angles and channels

Choosing Between an I-Beam and a Wide Flange Beam

Both wide flange beams and I-beams are reliable weight-bearing components for many applications. However, the best type will depend on your project’s specific requirements.

Wide Flange Beams

Compared to I-beams, wide flange beams have a wider flange and thicker web. Their design enables them to handle more weight, and they’re suitable for spans of up to 300 feet. Wide flange beams also feature a bevel that connects the web and top and bottom flanges. Lightweight wide flange beams—rather than I-beams—are typically used in residential construction projects.

Infra-Metals stocks W-beams from W4x13 to W44x335, with lengths up to 70 feet.

I-Beams

I-beams feature thinner webs and tapered flanges for a more lightweight construction. The I-beam’s shorter length makes it compatible with spans between 33 and 100 feet. Where wide flange beams come in three connected metal components, I-beam steel comes in a single metal piece.

Infra-Metals carries I-beams from S3x5.7 to S24x121, with various lengths up to 60 feet.

Contact Our Experts for Premium Steel Beam Solutions

I-beams and wide flange beams are vital construction elements in many types of structures. Now that you know the difference between wide flange beams vs. I-beams, you can select the best beam for your application depending on your engineering specifications.

Since 1990, Infra-Metals has been a premier provider of top-quality structural steel beams. In addition to I-beams and wide flange beams, we carry a selection of angles, tubes, plates, channels, solar panel mounts, and more. We also offer a variety of processing services, including drilling, cutting, blasting, and cambering.

All of our steel products for U.S. applications feature standard alloys specified by ASTM International (American Society for Testing and Materials). Infra-Metals is also a proud member of the Reliance Steel & Aluminum Co. family. We aim to serve as your one-stop shop for steel construction materials and processing.

Browse our catalog to view more of our offerings and capabilities, or request a quote at any time to get started on selecting the right solution for your application.

Josh Nesbitt – Operations Manager

Career Growth at Infra-Metals

Josh has held many roles in Atlanta, primarily focused on the processing side of the business. In 2006, he became the Processing Supervisor which was responsible for all plate processing and saw scheduling. He found his role challenging because of the diversity in machinery and the daily challenges of coordinating shipment and delivery schedules as well as managing personnel. CNC programming helped him gain additional experience, which made him a natural fit for the role given his knowledge as a plate burning operator. “Managing the differences between shifts was unexpected” due to the typical priorities between the shifts and yet it was Josh’s dynamic approach to the processing department that facilitated successfully the goal of prepping processed loads for on-time delivery.

Current Day-to-Day as Operations Manager

Josh is now responsible for the operations of the facility and it’s employees that work in the warehouse. He oversees all processing and production. With that in mind safety is the number one priority in our facilities and we want everyone to leave here the same way you showed up. “The safety of my employees is my number one concern.” Josh spearheaded the safety program in Atlanta. All jobs go through a JSA (Job Safety Analysis) followed up by a review of the job. We look for safety issues and explore ways to mitigate and eliminate them by incorporating JSO (Job Safety Observations). Everyday poses new challenges and Josh enjoys the pace, problem solving and order fulfillment processes all while running a safe environment for his employees.

Josh aspires to make the Atlanta division the best and most competitive location within the Infra-Metals family while nurturing the success of his employees. Starting his third decade with Infra-Metals, Josh continues looking for process improvement. “The safety of my employees are my #1 priority from the time I walk in that door.”