CNC Hi-Def Plasma Cutting

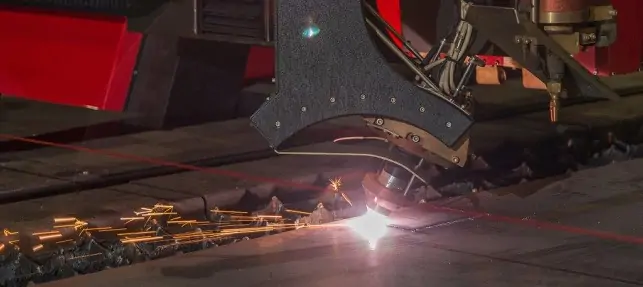

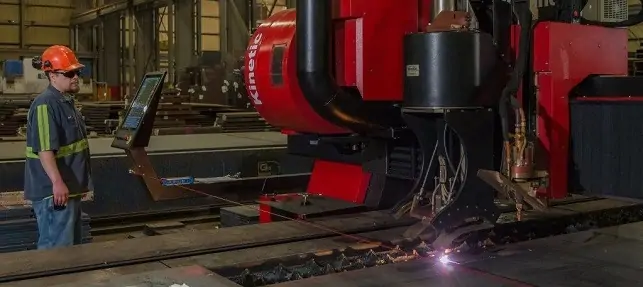

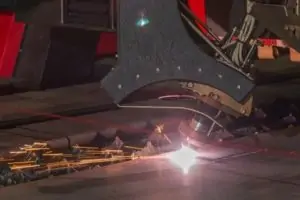

A process used to cut steel and aluminum to a desired shape utilizing a plasma torch. This process uses an electrical arc that is formed through an inert gas or compressed air turning that gas to plasma with temperatures approaching 40,000 deg F. The plasma heats the metal to its melting point and blows it away. The plasma burning machine utilizes its’ CNC capabilities to cut the desired shape. The CNC controlled machine is driven by a program that is prepared on site from a customer supplied drawing from either .NC1,.DXF or .DWG files, or from a hard copy blueprint.

The Hi-Def Plasma cutter uses a tighter nozzle than standard plasma cutting to concentrate the plasma arc, resulting in a higher tolerance finished product that requires little or no edge grinding. Provides extremely sharp top edge quality, shiny surface finish, and superior angularity with reduced angle variation.

Other operations performed on this machine are scribing items such as part numbers, centerlines, bend lines and center marks, to name a few.

Specifications

Hi-Def Plasma

Cut plate up to 3″ in thickness

Beveling up to 45 degrees in ¼”through 2” thick plate. Bevel types are A, V, Y, X and K and can be cut on complex profiles, both outside and inside contours.

Depending on the location we can accommodate plates up to 22’ x 87’ or 10’ x 80’

We use Primecut, Sigmanest and AutoCAD software

Oxy Fuel Plate Burning

Utilizing oxygen and propylene this process can cut through plate several inches thick. Driven by CNC (Computer Numerical Control) part programs it can produce shapes made to specific dimensions. Oxy-fuel is usually used to cut thicker material. Hi-def plasma gives a tighter tolerance and smoother cut and oxy-fuel burned material usually needs edge grinding as a secondary operation to finish the processing.

Burn up to 6” thick with up to 8 torches.

Can accommodate plates up to 10′ X 80′